The Future of Fashion: Exploring DTF Printing Innovation in the Fabric Market

Amongst these developments, Direct to Film (DTF) printing innovation has actually arised as an encouraging challenger, offering unique capabilities and chances for designers and manufacturers alike. This advanced printing technique has stimulated rate of interest due to its prospective to reinvent standard textile printing processes.

Evolution of Textile Printing

From the ancient civilizations making use of methods like block printing to the digital change of today, fabric printing has consistently pushed boundaries. As the craft spread to various other parts of the globe, new approaches such as display printing and roller printing emerged throughout the Industrial Revolution, changing the textile market.

In the 20th century, developments in technology brought about the advancement of rotating screen printing, permitting for faster and a lot more intricate layouts. The introduction of digital textile printing in the late 20th century marked a substantial shift in the direction of more functional and sustainable printing approaches. Today, with developments like Direct-to-Fabric (DTF) printing technology, designers can develop lively, comprehensive prints with greater performance and minimized ecological impact. The advancement of textile printing showcases an abundant history of imagination, resourcefulness, and technological development in the globe of fashion and style.

Advantages of DTF Modern Technology

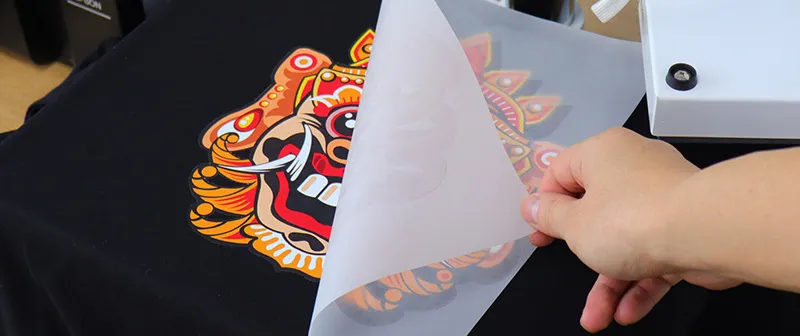

With the development of fabric printing techniques from ancient techniques like block printing to contemporary technologies such as digital printing, the introduction of Direct-to-Fabric (DTF) technology has significantly improved the efficiency and sustainability of textile printing processes. One of the main benefits of DTF innovation is its capability to directly print styles onto fabric without the requirement for transfer papers, which decreases waste and simplifies the production process. Additionally, DTF printing enables for higher color vibrancy and detail precision compared to standard approaches, making it possible for fabric makers to produce high-quality and detailed layouts effortlessly.

In addition, DTF technology is known for its flexibility, as it can be used on various kinds of materials, including natural fibers like woollen, cotton, and silk, in addition to artificial products such as polyester and nylon (DTF Printing). This adaptability opens a wide variety of possibilities for producers and developers to trying out different textures and products, causing more unique and cutting-edge products in the fashion business. In general, the implementation of DTF innovation represents a substantial improvement in fabric printing, offering countless advantages that add to the future sustainability and creativity of the sector

Sustainability in vogue Production

Stressing green practices is extremely important in contemporary style production, lining up with the expanding consumer need for lasting products. In the last few years, the garment industry has dealt with increasing examination as a result of its significant ecological influence, including extreme water use, chemical pollution, and fabric waste. As a response, lots of style brands are now including sustainable methods right into their manufacturing processes to decrease harm to the atmosphere.

Sustainability in style manufacturing encompasses different elements, such as making use of organic and recycled materials, minimizing energy usage, applying ethical labor methods, and advertising openness throughout the supply chain. In addition, developments in innovation, like DTF printing, deal possibilities to better enhance sustainability in textile production. This modern technology enables precise printing on fabrics, decreasing ink waste and water usage compared to standard printing techniques.

Style Flexibility and Modification

Furthermore, DTF printing facilitates modification on a scale previously unattainable, permitting for customized apparel and distinct items customized to individual choices. Overall, DTF printing innovation changes the design landscape in the fabric sector, offering limitless opportunities for creative expression and customized style.

Influence on Supply Chain & Market Trends

DTF printing technology in the fabric find out here sector is reshaping supply chain dynamics and affecting market fads with its effectiveness and customization capabilities. By allowing on-demand printing and getting rid of the requirement for large supplies, DTF innovation improves the supply chain process.

In addition, the customization possibility of DTF printing technology is reinventing the market fads in the textile industry. As an outcome, DTF modern technology is driving a shift in the direction of more cutting-edge and customer-centric methods within the fabric sector, shaping the future of fashion.

Final Thought

To conclude, DTF printing innovation is changing the textile industry by using countless benefits such as style modification, sustainability, and freedom. This cutting-edge modern technology is reshaping the future of fashion production, impacting supply chains, and driving market patterns towards a lot more eco-friendly and efficient practices. As the sector continues to evolve, DTF printing will play an important function fit the method textiles are produced and consumed in the years to come.

From the ancient civilizations using strategies like block printing more tips here to the electronic change of today, textile printing has constantly pushed borders. As the craft spread to various other components of the world, new methods such as display printing and roller printing arised throughout the Industrial Transformation, transforming the textile industry.

The intro of electronic textile printing in the late 20th century marked a substantial change in the direction of more flexible and sustainable printing methods.With the advancement of fabric printing techniques from old approaches like block printing to modern-day advancements such as digital printing, the intro of Direct-to-Fabric (DTF) modern technology has considerably boosted the performance and sustainability of textile printing procedures (DTF Printing).In action to the critical change towards sustainability in style manufacturing, the adoption of cutting-edge innovations like DTF printing not only addresses environmental problems however likewise opens up avenues for unrivaled layout freedom and personalization in the fabric market

Comments on “The Ultimate DTF Printing Guide: Methods, Materials, and Applications”